“bamboo supplier .060″” sheet stock”

Can polycarbonate sheets laser cut?

Polycarbonate is a bad choice for laser cutting. … It tends to melt rather than evaporate, and has a higher chance of catching fire and leaving molten gooey deposits on the vector cutting grid. It also does not engrave well (again, tends to melt).

What is the best way to cut polycarbonate? Polycarbonate sheets can be cut with either a circular saw or a jigsaw puzzle. A circular saw is the best tool for cutting larger polycarbonate lengths. Due to the properties of this material, polycarbonate will not crack or splinter around the cut.

What plastics are safe to laser cut?

Acrylic (Plexiglas, Lucite, PMMA) Acrylic is the best plastic to use in laser cutting because it cuts well and safely, comes in many colors and is useful for prototyping or a final product. Most places that have laser cutters will use acrylic.

Are all plastics safe to laser cut?

Safe materials The laser can cut or etch. The materials used by the laser can cut materials such as wood, paper, cork, and various types of plastic. Etching can be done on almost anything, wood, cardboard, aluminum, stainless steel, plastic, marble, stone, tile and glass.

Is polyethylene safe to laser cut?

Polyethylene does not easily absorb the energy of a 1.06 micron fiber laser. Cutting of polyethylene can be performed with a CO2 laser to produce a clean non-dyed cut with a slightly raised edge near the point of ablation. Laser engraving and laser marking of polyethylene are possible with a CO2 laser.

Can laser cut polypropylene sheets?

Polypropylene Overview Polypropylene does not easily absorb the energy of the 1.06 micron fiber laser. Polypropylene cutting can be performed with a CO2 laser to produce a clean non-stained cut with a slightly raised edge near the ablation point.

How do you cut polypropylene sheets?

Can laser cut plastic sheets?

The laser can cut or etch. The materials used by the laser can cut materials such as wood, paper, cork, and various types of plastic. Etching can be done on almost anything, wood, cardboard, aluminum, stainless steel, plastic, marble, stone, tile and glass.

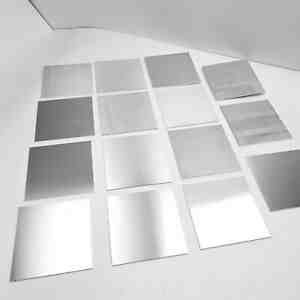

What metals can be laser etched?

Suitable metals for laser marking and engraving:

- Stainless steel.

- Aluminum.

- Anodized aluminum.

- Hardened metals.

- Alloy steel.

- High-speed steel.

What material can be laser marked? Laser marking is capable of engraving most metals. Lasers are also capable of marking plastics, ceramics, glass and silicon. Composites, graphite, rubber, and LEDs can be marked in black or any other color depending on the material.

Can aluminum be laser etched?

Aluminum is one of the most common materials in modern manufacturing. You can use industrial marking systems to engrave unique identifiers directly on aluminum pieces. Laser etching of aluminum is an efficient high-speed process during which laser radiation changes the micro-surface of the metal.

Can you laser etch anodized aluminum?

When it comes to marking old, the most common laser process is laser etching. With this process, you can mark anodized aluminum on the surface of the anodized layer. The result of the laser etching and the engraving of aluminum is a mark that has a high contrast with the anodizing color. …

Can you engrave on aluminum?

Aluminum is a thin metal that is easy to engrave with even the most basic tools. You can use the tip of a ballpoint pen to engrave an aluminum cake or a blunt metal stylus with variable size tips for more intricate engravings.

Can stainless steel be laser etched?

While laser etching can be used to mark stainless steel just as well, the flatter cuts made in the laser etching process mean that the designer or marking does not take long when the item comes under stress. To get the best cut in laser engraving, increase the power of the laser and reduce the marking speed.

Does engraved stainless steel rust?

Laser engraving stainless steel leads to corrosion In fact, any method that engages markings on the surface (deep or flat) will remove this layer. This thin protective layer consists of chromium oxide. Chromium oxide is naturally formed when chromium reacts with oxygen.

Can you laser etch steel?

Laser etching metal is possible to do at home with relatively low-power lasers. … The process is quite simple and works on a number of different metals. Stainless steel, aluminum and copper are the most commonly used materials for this process.

What can be laser etched?

The laser can cut or etch. The materials used by the laser can cut materials such as wood, paper, cork, and various types of plastic. Etching can be done on almost anything, wood, cardboard, aluminum, stainless steel, plastic, marble, stone, tile and glass.

What material can a laser cutter mark?

Fiber lasers are ideal for marking many types of aluminum, brass, copper, nickel-plated metals, stainless steel and more – as well as engineered plastics such as ABS, PEEK and polycarbonate.

What should you not laser engrave?

A laser machine can etch on almost anything. This includes aluminum, plastic, marble, glass, stainless steel and wood. Approach oily and resinous bushes with caution though, as they can catch fire. Engineering bushes are good, but they char too much when cut.

Can CO2 laser cut PVC?

The short answer: Sure, you can process PVC and vinyl in a CO2 laser. You can also cut your toenail with a circular power saw.

What happens when you cut PVC laser? PVC (Poly Vinyl Chloride) / Vinyl / Pleather / Artificial Leather Emit pure chlorine gas when cut! Never cut this material as it will ruin the optics, corrode the machine’s metal and ruin the motion control system. … ABS Emits cyanide gas and tends to melt ABS does not cut well in a laser cutter.

How thick can a CO2 laser cut?

Using oxygen as auxiliary gas, a CO2 CNC laser cutter of 150W and higher can cut a steel sheet of 1mm thick.

How thick of metal can a CO2 laser cut?

In terms of cutting capabilities, a 400W laser can be equipped with the laser cutting option: mild steel up to 4.8 mm thick. Stainless steel up to 3 mm thick (with oxygen aid)

How thick can a 80W CO2 laser cut?

An 80 watt laser can cut plywood up to 1/2 inch thick. Be sure to use a high pressure source of air to exclude all carring during the cutting process so that the laser works efficiently.

What plastic is safe to laser cut?

Acrylic (Plexiglas, Lucite, PMMA) Acrylic is the best plastic to use in laser cutting because it cuts well and safely, comes in many colors and is useful for prototyping or a final product. Most places that have laser cutters will use acrylic.

Is polypropylene safe to laser cut?

Polypropylene does not easily absorb the energy of the 1.06 micron fiber laser. Polypropylene cutting can be performed with a CO2 laser to produce a clean non-stained cut with a slightly raised edge near the ablation point. Laser engraving and laser marking of polypropylene are possible with a CO2 laser.

Is polyethylene safe to laser cut?

Polyethylene does not easily absorb the energy of a 1.06 micron fiber laser. Cutting of polyethylene can be performed with a CO2 laser to produce a clean non-dyed cut with a slightly raised edge near the point of ablation. Laser engraving and laser marking of polyethylene are possible with a CO2 laser.

Can fiber laser engrave metal?

For bare metals, fiber lasers represent the engraving method of choice. Fiber lasers are ideal for marking many types of aluminum, brass, copper, nickel-plated metals, stainless steel and more – as well as engineered plastics such as ABS, PEEK and polycarbonate.

Can fiber laser engrave? Fiber lasers are used in many industries like the electronics industry because of the ability to mark on small things as well as in the jewelry industry for engraving the brand identity or name of the owner. They can be applied to materials such as metals (steel, aluminum, copper, etc.), plastics, carbon fiber, etc.

What kind of laser do I need to engrave metal?

At least 50 watts fiber laser power is recommended for metal laser cutting or engraving. Forty or 50 watt fiber laser power can be used for direct laser marking metals. Twenty-five to 150 watts of CO2 laser power is recommended for direct marking of metals.

Can a 10W laser engrave metal?

The same device (a 10W DPSS laser) with high power of 90% and 400 mm / min speed makes a black or dark gray engraving on copper, zinc, brass or bronze.

Can a 15 watt laser engrave metal?

The 15 W blue laser head can mark stainless steel at 33 mm / s. You can not engrave tool steel and high-carbon content steel types with a 6 W blue laser. However, our tests have shown that a 15 W blue laser head can engrave high-speed steel as well as mild steel.

What will a fiber laser mark?

Fiber laser markers have a wavelength of 1090 nm, which is in the standard wavelength range, and are capable of marking a wide range of materials, including metals and resins. Their high strength is particularly suitable for black-annealed marking and deep engraving on metal.

Can a fiber laser engrave plastic?

The laser fiber engraving machines have a wide range of applications in the plastics industry. … The fiber laser technology is very different from the UV laser technology, yet the fiber laser technology can mark over different plastic materials which are not transparent.

Can a fiber laser mark acrylic?

Cast acrylic can be cut with a laser, but it will not result in flame-polished edges.

Can a laser engraver work on metal?

Laser engraving has the ability to work on a variety of materials, especially when it comes to metals. Some of the metal surfaces you can work with include: Various grades of steel. Stainless steel.

Can a laser printer print on metal?

Typical metals for laser printing include: Fiber laser marking is most commonly used to place critical marks or codes on STAINLESS STEEL surfaces. … CO2 laser marking systems that use shorter wavelengths than traditional CO2 laser wavelengths can be used to create marks on metal surfaces such as anodized aluminum.

Can a 15 watt laser engrave metal?

The 15 W blue laser head can mark stainless steel at 33 mm / s. You can not engrave tool steel and high-carbon content steel types with a 6 W blue laser. However, our tests have shown that a 15 W blue laser head can engrave high-speed steel as well as mild steel.

Can lasers cut stone?

While laser machines do not cut stone material, you can efficiently and effectively laser engrave stone with a CO₂ laser engraving machine. … For best laser engraving results use dark, polished and natural types of stone such as granite, marble and basalt.

Can a laser cut something? Laser cutting is so popular mainly because of its versatility. Laser cutters can cut a wide variety of materials – everything from paper, wood, cork, acrylic and foam to various types of metals. Nevertheless, there are some materials that seem to fit well into this list, but should never be cut with a laser cutter.

Can you laser on rocks?

Laser engraving stone slabs or rocks with a polished texture or very smooth surface gives the best results. … Natural stones with a round surface can still be laser engraved, simply place the object on a horizontal plane. We also recommend using a support to help with this process, such as clay models.

Can you engrave on a rock?

Look for an electric engraver or rotary tool that allows you to change the tip. A carbide tip is suitable for engraving softer stones such as sandstone, limestone or soapstone. A diamond tip is best for engraving harder stone or glass. Engraving tips come in different shapes and widths.

Can you laser engrave on stone?

Laser engraving on stone is particularly suitable for polished, ideally dark natural stones such as granite, marble, or basalt. The more homogeneous and fine-grained the stone, the better the results of the stone engraving. However, even pebbles can be laser processed well through the smooth surface.

Can a laser cutter cut rocks?

Stone comes in all shapes and sizes, from river rocks to quarried quartz, and engraves surprisingly well with a laser cutter.

Can a laser cutter cut anything?

Safe materials The laser can cut or etch. The materials used by the laser can cut materials such as wood, paper, cork, and various types of plastic. Etching can be done on almost anything, wood, cardboard, aluminum, stainless steel, plastic, marble, stone, tile and glass.

Can laser melt rock?

Modern high power lasers have enough power to melt and vaporize all types of rocks.

What can lasers not cut?

| Material: | Danger: |

|---|---|

| PVC (Poly Vinyl Chloride) / Vinyl / Pleather / artificial leather | Emit pure chlorine gas when cutting! |

| ABS | Emits cyanide gas and tends to melt |

| Thick (> 1mm) polycarbonate / Lexan | Very bad cut, discolored, burn |

| HDPE / milk bottle plastic | Start fire and melt |

What limitations does the laser cutter have?

What are the disadvantages of laser cutting? Although used to produce parts in almost every industry, laser cutting has its drawbacks. Namely, need for expertise, restrictions on metal thickness, cost and hazardous fumes are all things you should consider before turning to laser cutting.

What Cannot be cut by laser?

Polycarbonate is a bad choice for laser cutting. ABS Emits cyanide gas and tends to melt ABS does not cut well in a laser cutter. It tends to melt rather than evaporate, and has a higher chance of catching fire and leaving molten gooey deposits on the vector cutting grid.

What material is used for laser cutting?

Safe materials The materials that can cut the laser materials such as wood, paper, cork and some types of plastic. Etching can be done on almost anything, wood, cardboard, aluminum, stainless steel, plastic, marble, stone, tile and glass.

What board is used for laser cutting? We offer 4 main materials for laser cutting: plywood, MDF, acrylic and cardboard. Each of them can be rejected, in different types, colors and thicknesses, a total of more than 60 material options.

What materials are used for laser printing?

Laser cutting material: MDF, plywood, metals, acrylic, cardboard.

Can laser printers print on any paper?

If your goal is to print on any paper you print or find for the lowest price, laser printers are great. As long as a paper does not damage it, a laser printer can usually generate excellent image quality on any type of paper.

What materials can be used in a laser printer?

| Material | mark |

|---|---|

| stainless steel | š « |

| Metal, painted | |

| Brass | š « |

| Copper | š « |

What plastic is used for laser cutting?

Polypropylene. A durable and flexible material ideal for laser marking and cutting. Polypropylene is a popular manufacturing plastic that is used in a wide variety of applications in a wide variety of industries.

What plastics Cannot be laser cut?

| Material: | Danger: |

|---|---|

| PVC (Poly Vinyl Chloride) / Vinyl / Pleather / artificial leather | Emit pure chlorine gas when cutting! |

| ABS | Emits cyanide gas and tends to melt |

| Thick (> 1mm) polycarbonate / Lexan | Very bad cut, discolored, burn |

| HDPE / milk bottle plastic | Start fire and melt |

What kind of plastic can be lasered?

The large number of different types of industrial lasers now available has expanded the range of plastics suitable for laser processing – from polyimide to polyester, polypropylene, acrylic and PTFE.

Sources :

Comments are closed.