Bamboo polymer composite sheet

What is poly composite?

Polymer composites are a mixture of polymers (i.e., thermosets or thermoplastics) with various continuous and discontinuous reinforcements / fillers, mainly added to polymers to improve material performance. Polymer compounds are increasingly being used in various fields of engineering.

What are the 3 types of compounds? The most common type is polymer matrix compounds, however, metal matrix compounds, and ceramic matrix compounds are also common, as are natural compounds such as wood.

What is polymer composite example?

Examples are graphite / epoxy, Kevlar / epoxy, and boron / epoxy compounds. Advanced compounds are traditionally used in the aerospace industries, but these materials have now found applications in the commercial industries as well.

What are the polymer matrix composites and give its examples?

Polymer matrix composites are used as components in a wide range of medical devices; such as MRI scanners, C scanners, X-ray sofas, mammography plates, tables, surgical target tools, wheelchairs, and prosthetics.

Is composite a polymer?

Composites, also known as Fiber-Reinforced Polymer (FRP) composites, are made of a polymer matrix that is reinforced with worked, man-made or natural fibers (such as glass, carbon or aramid) or other materials of reinforcement.

Is composite A good material?

In general, composite materials are very durable. Another advantage of composite materials is that they provide design flexibility. Compounds can be formed into complex shapes – a big advantage when producing something like a surfboard or a boat hull.

What kind of material is composite?

composite material, also called composite, a solid material that results when two or more different substances, each with its own characteristics, are combined to create a new substance whose properties are superior to those of the original components in a specific application.

What is the advantage of composite material?

Advantages of Composite Materials Design Flexibility – Thermoset Composites give designers almost unlimited flexibility in designing molds and shapes. They are formed into the most complex components and can be made into a wide range of densities and chemical formulations to have precise performance properties.

What are polymer composites used for?

Polymer matrix composites are used as components in a wide range of medical devices; such as MRI scanners, C scanners, X-ray sofas, mammography plates, tables, surgical target tools, wheelchairs, and prosthetics.

What can composites be used for?

Composites are now being used in vehicle and equipment applications, including, panels, frames, interior components and other parts. Some composite infrastructure applications include buildings, roads, bridges and pilings.

Why are polymers used in composites?

Polymers that are often used as compounds are either thermoplastic polymers, thermosetting polymers or elastomers. They are a source of a wide variety of low-cost raw materials that offer many advantages such as [1]: Low specific weight. High anti-corrosion material stability.

What is not polymer?

Examples of non – polymeric materials include: Elements. Metals. Ionic compounds, such as salt.

Why is glucose not a polymer? Glucose is a monomer and not a polymer as it is a single unit. DNA, Cellulose, Starch are a prime example of natural polymers. The most abundant natural monomer is glucose, which is bound by glycosidic bonds in the polymers of cellulose, starch and glycogen.

What are the 4 types of polymers?

Types of polymers

- Natural polymers. Natural polymers are all found in nature. …

- Synthetic polymers. Synthetic or artificial polymers are manufactured in the laboratory and usually contain petroleum-derived ingredients. …

- Addition polymers. …

- Condensing polymers. …

- Rearrangement polymers. …

- Biodegradable polymers.

What are the 4 polymer classes?

There are four basic types of biological macromolecules: carbohydrates, lipids, proteins, and nucleic acids. These polymers are composed of different monomers and serve different functions.

What are the 4 natural polymers?

Examples of naturally occurring polymers are silk, wool, DNA, cellulose and proteins.

Which of the following is not a polymer biology?

Answer and Explanation: Triglycerides (a) and glucose (c) are not considered biological polymers.

What are the 4 biological polymers?

There are four basic types of biological macromolecules: carbohydrates, lipids, proteins, and nucleic acids. These polymers are composed of different monomers and serve different functions.

What are examples of polymers in biology?

Examples of natural polymers are cellulose, shellac and amber. Biopolymers such as proteins and nucleic acids play crucial roles in biological processes. Common synthetic polymers are Bakelite, neoprene, nylon, PVC (polyvinyl chloride), polystyrene, polyacrylonitrile and PVB (polyvinyl butyral).

Is concrete a polymer or composite?

Polymer concrete is a composite material in which the aggregate is bonded together in a matrix with a polymer binder.

Is the concrete composite? Concrete is a composite material made of a fine, coarse aggregate bonded together with a fluid cement (cement paste) that hardens (cures) over time. Concrete is the second most widely used substance in the world after water, and is the most widely used building material.

Is concrete an example of polymer?

12.1 Introduction. Polymer concrete is the composite material made by completely replacing conventional cement concrete cement hydrate binders with polymer binders or liquid resins, and is a kind of composite polymer polymer .

What is the meaning of polymer concrete?

Polymer concrete is the composite material made by completely replacing conventional cement concrete cement hydrate binders with polymer binders or liquid resins, and is a kind of composite polymer polymer .

Is concrete is a polymer?

What is Polymer Concrete? Polymer concrete is a composite material fabricated by the polymerization of a monomer / aggregate mixture. It is a compound that uses a synthetic organic polymer as a binder and is prepared by mixing a polymeric resin with an aggregate mixture.

Is cement a polymer?

Polymer cement concrete is a composite concrete consisting of a synthetic polymer in the binding material.

Is concrete a synthetic polymer?

Polymer cement concrete is a composite concrete consisting of a synthetic polymer in the binding material. Polymer concrete has advantages of higher properties, low energy requirements and low labor costs. It is also referred to as Portland Polymer Cement Concrete (PPCC) or Latex Modified Concrete (LMC).

Which polymer is used as cement?

| Material | Density kg / m3 | Compressive strength |

|---|---|---|

| Urea formaldehyde polymer concrete | 2260 | 37 MPa (5,400 psi) |

| Polyester concrete | N / A | 95 MPa (13,800 psi) |

| Epoxy concrete | N / A | 58 MPa (8,400 psi) |

Is concrete a polymer or ceramic?

Concrete is a ceramic compound made of water, sand, gravel, crushed stone, and cement. The ingredients are mixed well together, and poured into a form. After the concrete is completely dry, it has excellent compressive strength.

Is concrete is a ceramic?

Concrete is not officially ceramic but is rather a composite made of sand, aggregate and cement. With the addition of water the cement reacts to form a ceramic-like structure around the sand and aggregate particles.

What material category is concrete?

Concrete is a composite material consisting of a binder, which is typically cement, rough and fine aggregates, which are usually stone and sand, and water.

How do you make composite bamboo?

How to bind bamboo? Bamboo is difficult to assemble due to its anatomical, physical and chemical attributes. Bleaching and plasma treatments improve bamboo wetting and bonding performance. Double molecular weight phenol-formaldehyde adhesives are efficient for bamboo bonding.

How do you make bamboo fiber?

There are two ways to process bamboo into a fabric: mechanically or chemically. The mechanical process includes crushing the wooden part of the plant and then applying natural enzymes to break down the bamboo cell walls, creating a mushy mass. The natural fibers can then be mechanically combed and spun into yarn.

Which material is made from bamboo fiber?

Rayon is a semi-synthetic fiber made by chemically reshaping cellulose. Cellulose extracted from bamboo is suitable for processing into viscose rayon (rayon is also made from cellulose from other sources).

Can you make bamboo fabric at home?

Bamboo is a fast-growing plant, and does not require much care. It is a resource. As in flax – from which linen is made – the process of making bamboo fabric, when done without chemicals takes time.

What is bamboo fabric made of?

Bamboo fibers are all cellulose fiber extracted or manufactured from natural bamboo, but they vary widely. Textiles labeled as being made of bamboo are not usually made by mechanical crushing and refining. They are usually synthetic rayon made from cellulose extracted from bamboo.

Is bamboo a polyester fabric?

Bamboo fabric is generally a rayon-like textile made exclusively of bamboo. Rayon is not a new type of fabric. It was developed back in about 1855 but the term rayon was officially adopted in 1924. Man-made cellulosic fibers include viscose rayon, modal, lyocell, acetate, and cupro.

Is bamboo a good fabric?

Bamboo fabric is very strong and wonderfully resilient to such a soft material. It will not tablet or reveal easily so you can enjoy the good looking as new for as long as possible. In addition, each item is expertly made to give the wearer the benefit of the best natural properties of bamboo.

What is bamboo composite?

Hebel, a professor at the Swiss Federal Institute of Technology in Zurich (ETH), has developed a new material made from bamboo fibers mixed with organic resin. The material, called a bamboo composite material, can be pressed into any shape and then sawn or sanded like wood.

Is bamboo composite wood?

Bamboo makes a very fine, homogeneous and dense flour that mixes with recycled plastics. The finished board is usually covered on four sides and a super strong dense board is the result. Some boards are more than three times as strong as a traditional composite board. Some manufacturers offer unlimited boards.

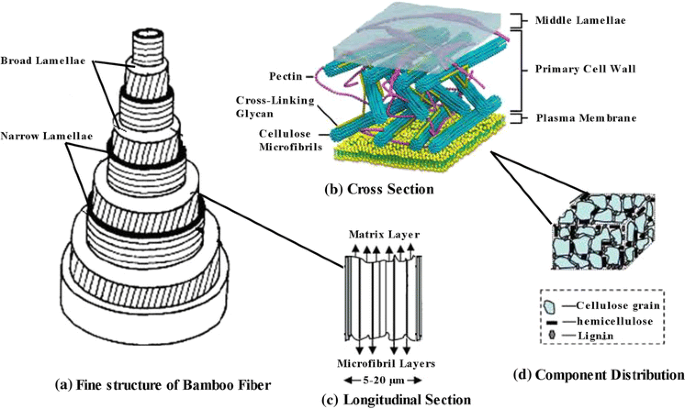

Is bamboo a natural composite?

Bamboo is a type of natural fiber composite that belongs to the plant fiber group. Bamboo is a type of stem fiber that can be found abundantly in tropical and subtropical countries.

What are the three general factors that determine the properties of a composite material?

Answer. Three factors are given in the test: (1) the materials of the components; (2) the geometric shapes of the constituents – the reinforcement phase in particular – and the resulting structure of the material; and (3) phase interaction.

What are the 3 main categories of composite materials? Organic, Polymeric or Reinforced-Plastics matrix composites.

What factors determine the properties of composites?

The mechanical properties of composite materials usually depend on the structure. Thus these properties typically depend on the form of inhomogenities, the volume fraction occupied by inhomogenities, and the interfaces between the components.

What are the four classifications of composite?

The classification of composite materials takes place at two different levels: The first classification criterion is based on the binder constituent. The main composite families include organic matrix compounds (OMCs), metal matrix compounds (MMCs), and ceramic matrix compounds (CMCs).

What are the properties of composites?

However, as a class of materials, composites tend to have the following characteristics: high strength; high modulus; low density; excellent resistance to fatigue, creep, creep cracking, corrosion, and wear; and a low coefficient of thermal expansion (CTE).

What are composites and its properties?

A composite material is a mixture of two materials with different physical and chemical properties. When combined they create a material that is specialized to do a certain job, for example to make it stronger, lighter or more resistant to electricity. They can also improve strength and stiffness.

What are composites?

A compound is a material made of two or more different materials which, when combined, are stronger than those individual materials alone. Simply put, compounds are a combination of components.

What is composite and its types?

Carbon fiber reinforced plastic. These types of compounds cover a range of different material combinations. The most common type is polymer matrix compounds, however, metal matrix compounds, and ceramic matrix compounds are also common, as are natural compounds such as wood.

Comments are closed.