Engineered bamboo wood floor cutter

What do you use to cut engineered wood flooring?

Can engineering wood be cut? How to cut engineered hardwood. Learning how to cut your engineered wood planks is an important part of the installation process. Fortunately, with the right tools, it’s a simple process. … Using a table saw, miter saw, circular saw, or hand saw, cut the plate with the finished side facing up.

Which saws are most commonly used for hardwood flooring projects?

The usual saws used to cut hardwood floors are the circular saw, the miter saw and the table saw. A circular saw is portable and can make cuts, cross cuts and miter cuts. A miter saw is best used for making cross cuts and precise miter cuts. A table saw is best used for making precise cuts.

What is a flooring saw used for?

If you are installing your own laminate flooring, vinyl or wood flooring, you will need a floor saw. These tools will allow you to create the necessary cross-sections, break-cuts, and miters.

What is the best saw for cutting wood?

Here are the best hand saws of 2021

- Best Hand Saw Overall: 15-inch DeWalt DWHT20544L Tooth Saw.

- The best stretch saw: Irwin Tools 213101 12-inch traction saw.

- Best mech saw: Lenox Tools 12132HT50 12 inch mech saw.

- Best blow saw: Irwin Tools 2014400 ProTouch Coping Saw.

- Best Punch Saw: Klein Tools 31737 Gypsum Saw 5.2 Inch.

What do you use to cut engineered hardwood?

You may need to cut the first board with a circular saw or miter saw with a blade designed for engineered wood flooring. When you encounter columns or doors, cut the planks so that they fit on both sides, taking care to keep the expansion gap open.

How do you rip engineered hardwood floors?

When the boards are broken to fit them, the tongue side of each board will be the cut. You can make a straight tear with a fence as long as it does not lead to a hole in one end of the board that is wider than the plinth that covers it. Otherwise, it is best to pluck the tables freehand, either with a table saw or a circular saw.

Can you use a miter saw to cut wood flooring?

What do you use to cut hardwood floors? A miter saw is your best option if you can only buy or rent one type of saw. It has a flat surface to support the board or molding. You can make straight or angled cuts for corners or chevron-patterned floors.

Can bamboo flooring be nailed down?

What you should know: Bamboo floors can be nailed or glued to wooden floors or glued directly to concrete basements above, above, or below ground level (i.e. basements). All plank flooring should be installed perpendicular to the floor joist. The installation of nails is most commonly used on wooden floors.

Is it necessary to glue the bamboo floor? You can choose to glue the bamboo directly to the concrete or float it on a bottom layer. If you choose to glue the bamboo to the concrete, you should use a flexible floor adhesive.

Can solid bamboo flooring be nailed down?

Keep in mind that the only bamboo floors that can be nailed are our horizontal and vertical bamboo range. Woven bamboo yarn is too strong to be nailed to the ground. For more tips and advice on installing bamboo flooring, see our Installation and Installation Guide.

Can you walk on engineered hardwood floors after installation?

Engineered hardwood floors can withstand the deformation of temperature changes much better than solid wood floors, so you only have to wait a day before walking on them.

How soon can you walk on hardwood floors of engineering? Allow at least two days to complete this project. You can’t walk on new ground for 24 hours, so plan your work accordingly. You may have to leave a trail on the promenade and complete the ground the next day. Check all plates for warping and defects.

How long before you can put furniture on new engineered hardwood floors?

We recommend that you wait 6 hours before walking around your new flats with socks. After 24 hours, you can walk in shoes. Leave for 48 hours before placing the furniture and returning the pets. Carpets and rugs can be laid out after a full week.

How long does it take engineered hardwood to dry?

Use a humidity meter. Keep in mind that it can take 4 to 6 weeks (and sometimes longer) for your floors to dry completely. It is essential that you wait for the floors to dry and settle before polishing them.

Can you put furniture on new hardwood floors?

We recommend waiting at least 24 hours before stepping on the floor and even then wearing only hardwood socks. Wait a total of four days before moving the furniture back to give it enough time to sit down.

How long do engineered hardwood floors need to acclimate?

It is more resistant to possible expansion or contraction due to changes in humidity. However, manufacturers still recommend acclimatizing engineered hardwood floors for at least 48 hours or until they reach moisture stability at the top of the veneer or plywood core.

Does engineered hardwood need to acclimate before installation?

Manufacturers still recommend acclimatizing hardwood floors for at least 48 hours or until they reach their acceptable moisture content. Do this inside the room where they will be installed. Its plywood core helps mitigate dimensional changes but does not completely eliminate it.

How do you acclimate engineered flooring?

The easiest and most common way to acclimatize is to place the cardboard in the room where you installed it at least three days in advance (longer is always better). If you have a room, space the cardboard. Otherwise, the cartons can be stacked (but staggered) to allow as much air to circulate as possible.

How long does engineered hardwood take to settle?

Good practices for acclimatizing wood floors Acclimatization times vary by species and product, but a general rule of thumb is to acclimatize wood floors for at least three days. You are trying to strike a balance between the moisture content of wood materials and the air in which the product is installed.

Does engineered hardwood expand and contract?

Due to this process, the wood floor is not as much affected by moisture as the wood. It does not shrink or expand, making it resistant to deformation and build-up. And for the same reason it is considered very strong and stable.

Will engineered wood floor settle?

Although they are more stable than solid wood flooring, engineered wood flooring will still move slightly, so it’s best to let the engineered wood flooring “settle” into your new environment before installing it. We recommend a minimum of two days between receiving your floor and installation.

Where do you cut bamboo?

If you look closely at the stem of your lucky bamboo plant, you will see clearly defined rings, called nodes. Make the pruning cut just above one of the nodes. Your cuts should be clean and smooth to minimize the chances of infection. It is not necessary to cut the shoots or the stem at an angle.

Does the bamboo grow back when it is cut? Cutting the top Removing the top of the bamboo will not result in a growth of the cane, but new leaves will grow from the cut. These leaves provide energy to the plant’s underground system, allowing new reeds to sprout.

Can I cut off the top of my bamboo plant?

You can also roll up (remove the top) bamboo to create a lush topiary look. Once covered, the bamboo will not grow back vertically. … Make sure you leave viable limbs and cut about 1/4 inch above the node when you finish the bamboo. Without limbs, the cane cannot survive.

Does bamboo stop growing if you cut the top?

Removing the top of the bamboo will not result in a growth of the cane, but new leaves will grow from the cut. These leaves provide energy to the plant’s underground system, allowing new reeds to sprout.

Can you trim a bamboo plant?

Pruning the lucky bamboo plant Using very sharp, sterile pruning shears, cut the shoots that are thin, too long, or that grow crooked. … Cut back shoots to a length of 1 or 2 inches (2.5-5 cm.) From the stem. This will encourage more shoots to grow from the cutting area and create a denser, bushy appearance.

Can you cut bamboo with circular saw?

Almost any type of sawmill or carpentry should work to cut bamboo. Hand saws are totally suitable because bamboo is easy to saw as it is hollow. … Craftsmen use everything from small band saws to large circular saw blades.

How to cut bamboo stems? Cut the lucky bamboo To cut a cut stem, cut it into clean, sharp pieces just above a knot. Trim the new growth over a node in the new section or cut it where it joins the main stem to completely remove the bud. It is best to cut the bamboo during the slower growing winter period.

What is the best tool to cut down bamboo?

Ripe bamboo tops can be cut with a pruning saw or, in the case of wood species, with a chainsaw. While a pruning saw can be used on thick, woody tops up to 6 inches in diameter, an electric hand saw makes the job easier. Chainsaw cutters and electric or gas chainsaws can also be used to cut bamboo culms.

Is bamboo hard to cut?

Bamboo has many advantages over other types of wood. … The qualities that make bamboo so great for so many projects do have one drawback: they make wood harder to cut than other types. However, it is possible to cut bamboo with a sharp instrument.

What is best tool to cut bamboo?

So what is the best outdoor bamboo cutting tool? Cutters are a good choice if you need a tool for pruning, trimming, or doing lighter work, such as lifting bamboo. A machete is ideal if you need to clean undergrowth or large groups, cut out suction cups, and even make clean, chipless cuts through your ass.

How do you cut bamboo without it splitting?

You don’t want the bamboo canes to break as they dry. To avoid this, wrap a thin gauge cord around both ends of each segment, 1 inch or less from the cut ends. Rotate the cable until it is tight. Wrapped in this way, the bamboo canes will not break or split.

How do you cut bamboo cleanly?

Cut at a 45 degree angle and make sure your knife is sharp enough so that the cut is clean and not serrated. Select a joint on the stem and cut it just above. Remove the leafy shoots from the bottom of the stems. Don’t forget to water the bamboo stalks, though then put them in a decorative vase.

How do you cut bamboo so it doesn’t split?

Any cutting tool can be used, including a chainsaw or reciprocating saw with a fine-toothed blade, but an economical cutting saw also produces a clean cut. When cutting the culms, cut the bamboo just above a node to prevent it from being crushed or broken.

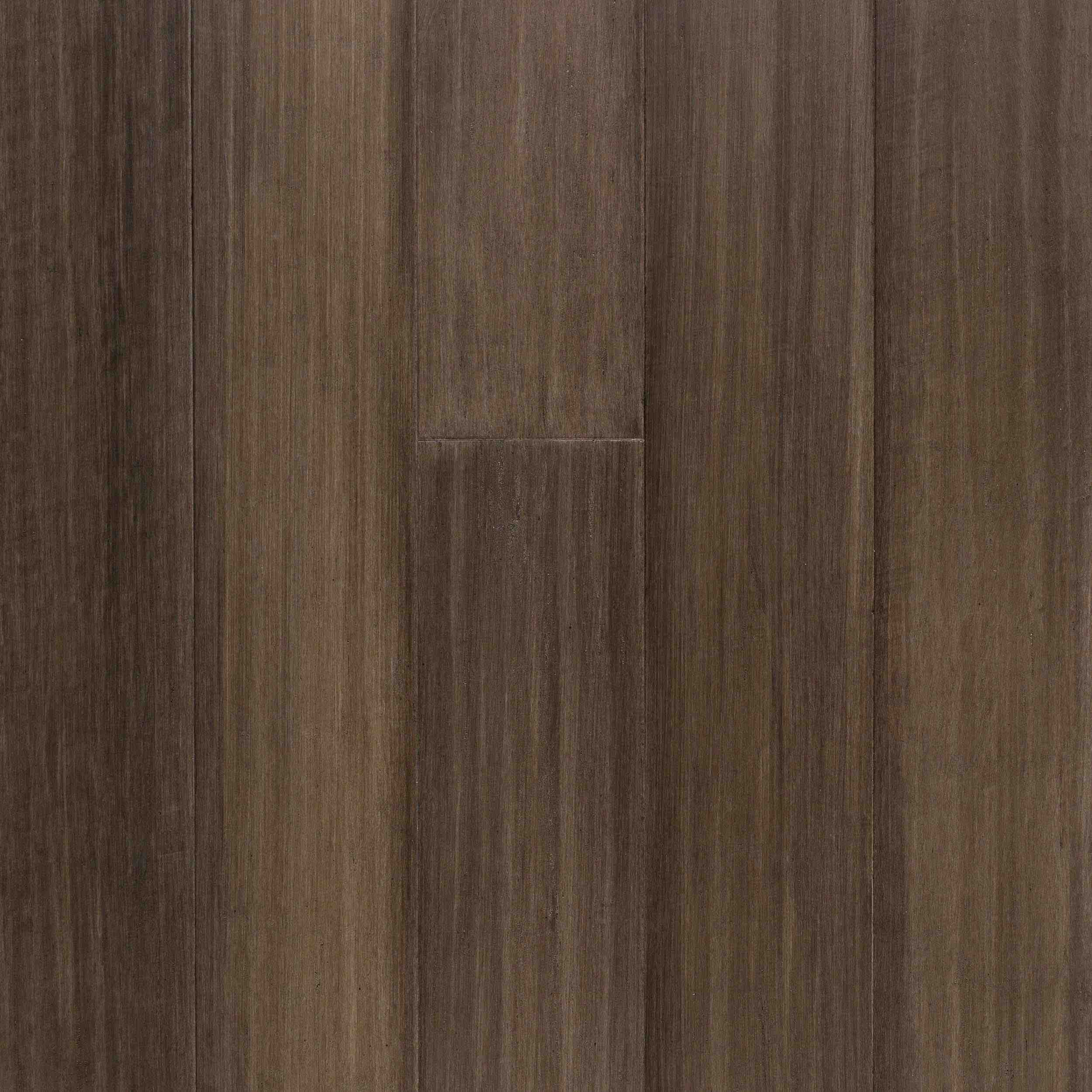

Is bamboo wood hard to cut?

Although technically a grass, dry bamboo cuts like dense hardwood. … First, because of its long, sharp grain, bamboo breaks easily, especially when the grain is cut or fitted [opening photo] or when edge profiles are routed [Top Photo].

Is bamboo hard on saw blades?

Wire bamboo is the densest hardwood on the market. It is almost three times the strength of an oak ground, with an average Janka hardness above 4,000!

What is the best tool to cut bamboo?

So what is the best outdoor bamboo cutting tool? Cutters are a good choice if you need a tool for pruning, trimming, or doing lighter work, such as lifting bamboo. A machete is ideal if you need to clean undergrowth or large groups, cut out suction cups, and even make clean, chipless cuts through your ass.

Can bamboo be turned into lumber?

Bamboo wood products are made of cut bamboo strips from the thick walls of the hollow stem. … The strips can be laminated edge to edge to create a thin single-layer panel, or they can be laminated back together, creating multilayer bamboo plywood. The pieces can also be glued frontally to create vertical grain panels.

Can bamboo be used as wood? Bamboo is extremely easy to machine with common woodworking tools, although it tends to crack when cut through grain. In addition, bamboo is naturally resistant to moisture. This feature makes it very suitable for items such as cutting boards and countertops, although a finish is still recommended. COST.

Sources :

Comments are closed.